Friday, October 28, 2022

“I have been urging companies to do more, faster, and better – and now that I have had a chance to actually show how it’s done, it didn’t turn out to be that easy,” Minja Orava laughs. She has just explained that before starting to work as Varusteleka’s irresponsibility coordinator, she used to work with civil society and activism. Varusteleka is an outdoor and army store from Finland, serving online customers worldwide. Climate action has become one of the strategic goals of the company as an initiative by the company founder Valtteri Lindholm.

“To provide some context to our climate action and emission calculations, our company has around 60 employees, and all our functions, meaning our office, store, and warehouse, are on the same premises. When it comes to products, almost half of our sales come from our own brand products – these are mainly textiles, knives, and shoes. Around 35% of our sales originate from exports and most of those are shipped to Northern America,” Orava explains.

"The more companies are asking questions from suppliers, the more it pushes everyone in a value chain to do their share."

In addition to the company operations, Varusteleka has taken climate responsibility for producing and shipping its brand products. This means the whole life cycle of a product until the point it arrives to customers. Of these emissions, the company has data on and has control over. “What we still need is finding good enough proxies to calculate a carbon footprint for all the products we sell and transporting those to our premises. We currently have enough data only of our own brand products. Therefore, we have chosen to omit the emissions of other products for now,” Orava says.

Getting reliable data means asking lots of questions from suppliers. Orava thinks that as a company, Varusteleka can create a snowball effect by asking these questions and the more companies are doing this, the more it pushes everyone in a value chain to do their share. Varusteleka aims to get as accurate data as possible from its suppliers. As the company uses lifecycle emissions in calculations, it is important to know, for example, what are the emissions caused by manufacturing solar panels, in case those are used as an energy source in the supplier’s factory.

“Our climate action plan is dictated by the planet”

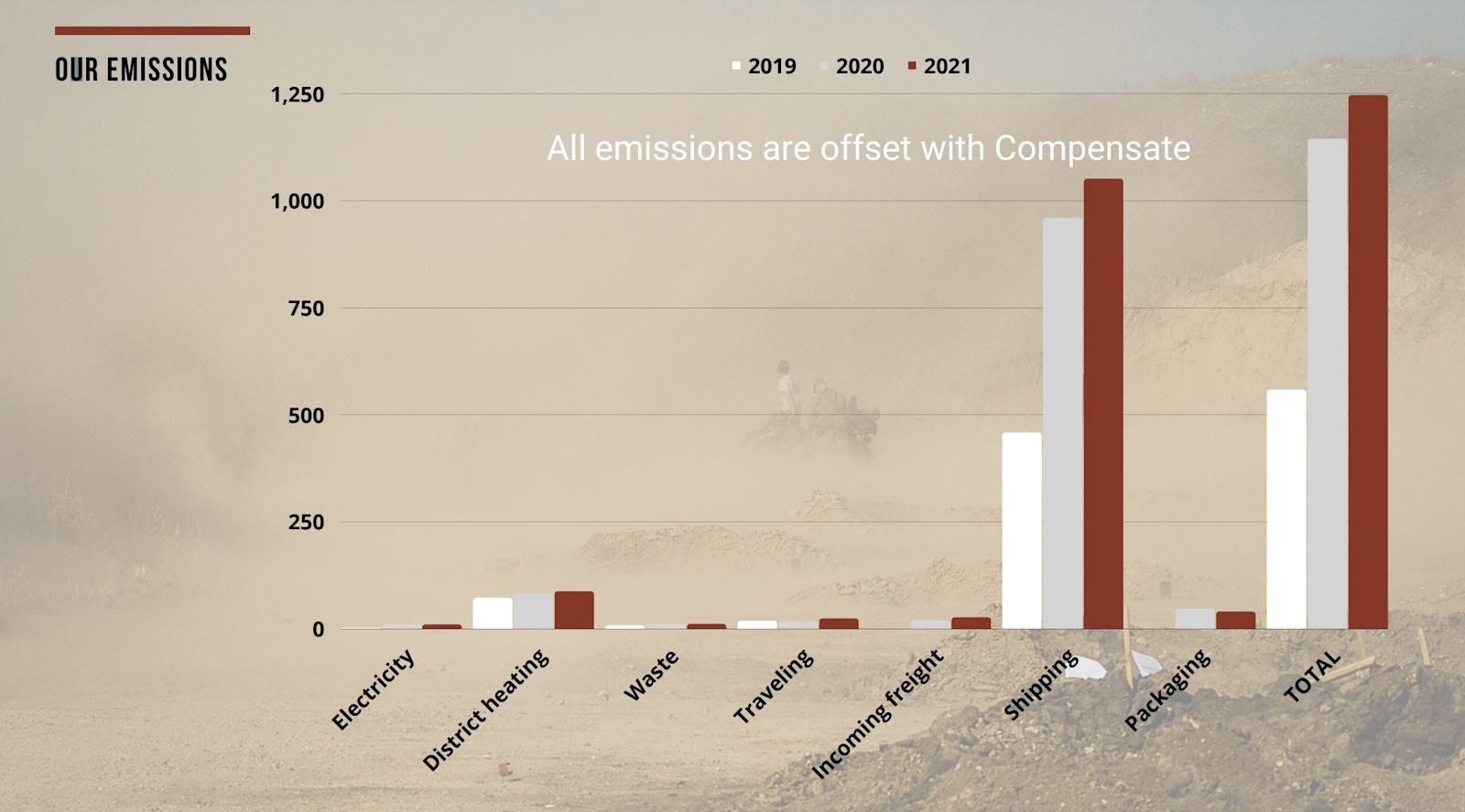

The majority of Varusteleka’s emissions come from shipping the products to customers. The second largest source of emissions is producing the company’s brand products.

“Here I want to highlight that when comparing the emissions of shipping the product to end-users to those caused by transporting the goods to our warehouse from factories, the incoming freight is quite marginal. For us, this means that we need to put emphasis on reducing the emissions of shipping,” Orava explains.

The breakdown of Varusteleka's emissions, excluding product emissions

Varusteleka has set climate targets according to the recommendations and climate science. This means halving the company’s scope 1 and 2 emissions and offsetting the rest by 2025. In addition, Varusteleka is aiming to be net zero already in 2030, which means halving the scope 3 emissions and offsetting the rest by 2030. “I would say that even 1.5 degrees of warming leads to quite catastrophic consequences in a lot of areas on the planet. Halving our emissions is the bare minimum we should aim for.”

“When we started the discussion about emission reductions and made a public commitment, we didn’t have a clear plan on how to get there. We discussed if we should have some sort of policies but came to the conclusion that our plan is actually dictated by the planet and it’s not up to us to decide where we put the target. Our job is simply to ensure that we reach that goal.”

Understanding the carbon footprint of each item helps to design more climate-friendly products

After calculating the carbon footprint for the company’s brand products, Varusteleka published this data on its

“Communicating these footprints to our customers doesn’t mean we want to make individuals responsible for our emissions. Knowing the footprint helps us to design products with smaller carbon footprint and it also helps us to estimate the cost of offsetting for these products,” Orava mentions.

According to Varusteleka's calculations, its Fishtail Parka has a carbon footprint of 38.69 kg CO2e. This information is available for customers on Varusteleka's global web store.

All-in-all, Orava considers the calculations as “quite an easy exercise”. Varusteleka was able to automate those in the company’s ERP system, using existing product data. If data wasn’t available, the company used the worst possible emission factor. “Our calculations use the weight of the product, the country of origin for the product, and material composition. What we don’t take into account is the different size variations of each product, but we use a median instead.”

“We didn’t really have lots of benchmarks when we started this project. We have used the GHG protocol in the background – however, there are still many options in how you can actually execute these calculations in real life. Our calculations are based on the secondary data from the supply chains, using emission factors that are relevant to the whole textile industry. We could have collected primary data from our supply chain but that would have probably taken years since many of the suppliers don’t have this data. We wanted to make things happen faster,” Orava explains.

The priority should be on emission reductions, not on fine-tuning the calculations

Orava considers saving time and resources as crucial in environmental work. Not all companies have the luxury of hiring a sustainability professional – it is common especially in SME's that the duties are combined with, for example, communications duties.

“The hardest part is to reduce emissions and it also should be the priority, instead of fine-tuning the calculations. In our case, we can quite easily affect scope 1 and 2 emissions by improving energy efficiency and making smarter energy purchases. For scope 3, we need to get rid of most of the air cargo and manufacture our products with smaller carbon footprint by, for example, choosing different materials and also pushing the factories to make better decisions when it comes to energy sources.”

Orava says that all this requires huge strategic changes in the company. “We still don’t know how to get to net zero, but we are currently mapping the stages and looking into what are the different elements we can change.”

Varusteleka is offsetting its emissions with Compensate, something that the company founder Lindholm has demanded to do. The compensation covers the emissions of Varusteleka’s own operations, logistics, and manufacturing of the brand products.

“We now have a concrete cost for emissions and an incentive to reduce them. This makes my life a lot easier, as I can compare the cost of making more sustainable choices to the cost of offsetting. As an example, renewable energy tends to be more expensive but when screening our offsetting invoice at the end of the year, it’s cheaper to purchase renewable energy than to compensate for the energy that is based on fossil fuels. As the price of high quality offsetting keeps getting higher, compensation is a good whip for us to do more and to do faster,” Orava concludes.

This article is based on the Compensate webinar: How to start taking climate action and set climate targets. The webinar took place in October 2022 and can be